What Are the Standards for Switchboard Matting?

If you’re an office or facility manager, you know that safety should always be your top priority. This means that any workplace with high-voltage electrical equipment must consider switchboard matting to protect their employees and avoid costly accidents. Learn more about the most important standards for switchboard matting that every business manager should know.

The Purpose of Switchboard Matting

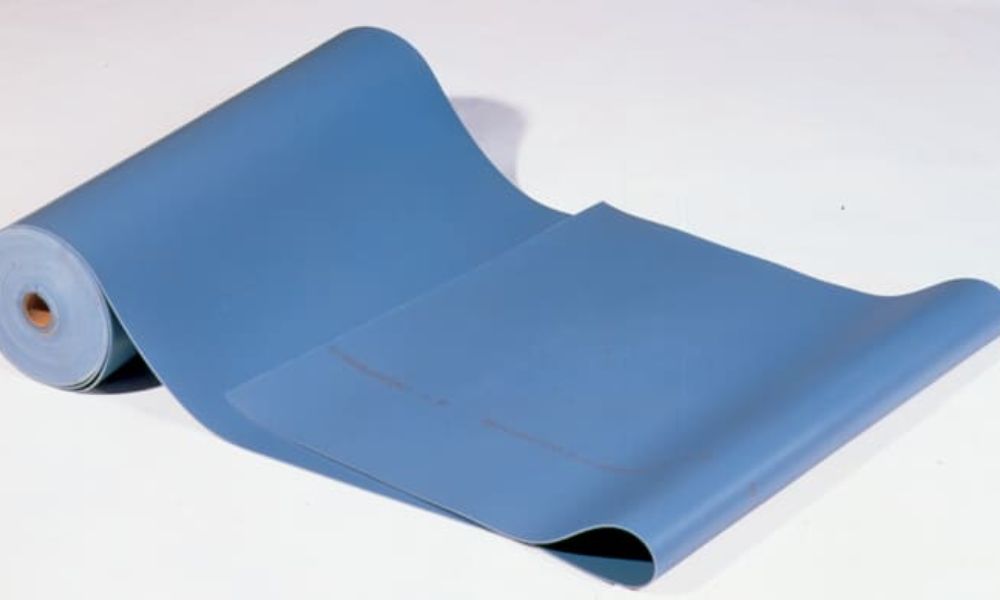

Switchboard matting is a protective covering that shields workers in high-voltage environments, such as data centers and power rooms, from dangerous electrical contact. A high-quality switchboard mat acts as an insulative barrier between the employees and live electrical equipment, significantly reducing the risk of electric shock. Some additional benefits of switchboard matting include preventing slips, reducing fatigue, and improving overall workplace safety.

ASTM D178 Standard Specification for Switchboard Matting

When selecting switchboard matting, it’s essential to ensure the material meets the standards established by ASTM International. The most widely recognized and accepted standard for switchboard matting is ASTM D178, the standard specification for electrical insulating rubber matting. This specification outlines the critical requirements for electrical insulating rubber matting, such as:

- Dimensions and tolerances: This addresses the allowable thickness, width, and length of the matting to ensure adequate coverage and protection.

- Type and classification: This defines the two types (Type I and Type II) and four classes (Class 1, Class 2, Class 3, and Class 4) of switchboard matting, differing in terms of the materials used and the voltage protection each class provides.

- Physical properties: This specifies the essential properties, such as tensile strength, elongation, and tear resistance, which directly affect the matting’s durability and performance.

Additional Quality and Safety Standards

While the ASTM D178 standard is the primary guideline for switchboard matting, other standards can influence the quality and safety of these products. Some of these standards include:

OSHA Guidelines for Floor Safety

The Occupational Safety and Health Administration (OSHA) has specific guidelines for maintaining floor safety in industrial and commercial facilities. These guidelines emphasize the importance of providing secure, clean, and well-maintained floors to prevent hazards such as slips and falls.

ANSI/ISEA Z535.1 Safety Colors for Visibility

The American National Standards Institute (ANSI) and the International Safety Equipment Association (ISEA) have established a standard for safety colors. Incorporating these safety colors in switchboard matting design ensures the matting is easily visible.

Verification of Compliance With Standards

When purchasing switchboard matting for your facility, verify that the product meets the necessary quality and safety standards. Check for labels or certifications that indicate compliance with ASTM, OSHA, or ANSI/ISEA standards. Be cautious of lower-cost alternatives that may not meet these stringent standards, as these products may put your employees at risk.

Investing in high-quality switchboard matting ensures the well-being of your employees, and it is vital to maintaining a safe working environment. By following the ASTM D178 standards and selecting high-voltage rubber mats from trusted suppliers like Mats Inc., you can be confident that you’re providing a safe workspace while minimizing the risk of electrical accidents.