Ways To Prevent Static Shock in the Workplace

Static shock in the workplace endangers personnel and equipment. Implementing effective strategies to prevent static shock is essential for creating a safer and more comfortable work environment. Explore various ways to prevent static shock in the workplace.

Maintain Proper Humidity Levels

Low humidity is a key contributor to static charge accumulation on surfaces. To combat static buildup, employers should avoid low humidity levels in the workplace and aim for humidity levels between 40 and 60 percent. You can achieve and maintain these humidity levels by using humidifiers in your facility.

Ground Conductive Objects

Static charges are not completely avoidable, but you can dissipate them so they do not lead to static shocks. Grounding is an effective way to dissipate static charges and prevent static shock incidents. Use grounding straps or cables on electrical equipment, and be sure to ground electrical outlets and all conductive objects and work surfaces.

Use ESD Floor Coating or Covering

Electrostatic discharge (ESD) floor coatings and coverings prevent static discharge from building up on the floor and transferring to employees as they walk around. ESD floor coatings are paints or finishes, while ESD floor coverings include mats or carpets. You can choose the best option for your facility based on budget and needs. Both options help to dissipate electrical charges and reduce the risk of static shock.

Place Down Anti-Static Floor Mats

Anti-static mats can significantly reduce static shock buildup in a workspace. Anti-static floor mats are made from conductive fibers to drain static electricity away from workers and the technological equipment they are handling. As an added benefit, anti-static floor mats often double as anti-fatigue floor mats, reducing strain on employees while protecting them from static shock. Install anti-static floor mats in areas with sensitive electronic equipment or where static shock incidents are more likely.

Clean and Maintain Anti-Static Flooring

Anti-static flooring and mats cannot dissipate static charges effectively when dust, dirt, and debris build up on them. Regularly clean and maintain anti-static flooring and mats to ensure their effectiveness. Create a cleaning and inspection schedule, and adhere to it to keep your mats and flooring in good condition and continue to protect employees from static shops.

Wear Anti-Static Clothing

Certain fibers, such as cotton, silk, and polyester, have anti-static properties. Wearing these materials reduces the risk of static shock, even in environments with high static electricity levels. Educate employees on which materials are safe to wear to work, and encourage them to wear anti-static materials to reduce their risk of static shock on the job.

Wear Static-Safe PPE

Employees can also wear static-safe personal protective equipment (PPE) to reduce their risk of static shock. Equipment like anti-static gloves, aprons, and footwear will keep employees safe in environments with heightened static electricity risks. Clean and replace all PPE as needed to maintain its effectiveness in preventing static shock incidents.

Train Employees

Offer regular training sessions and refresher courses on static electricity hazards, prevention techniques, and best practices. Doing so can educate employees on which clothing prevents static shock and other best practices for working with electrical equipment. Also, keep employees up to date with procedural changes in your facility, and ensure they feel comfortable providing feedback on improved methods of reducing static shock risks in the workplace. Basically, make it easy for employees to report any static-related issues.

Recognize Best Practices

Recognize and reward employees who utilize what they learned in the training; this behavior contributes to a safer workplace environment. Creating an environment that uplifts safety and adherence to best practices will motivate more employees to stay safe at work. Seeing other employees practicing static-reducing methods will encourage workers to do the same, contributing to a safer workplace.

Use Ionizers and Purifiers

Static electricity results from an imbalance of electric charges on the surface of objects. Ionizers and air purifiers release ions that attach to charged particles, neutralizing static charges. Placing ionizers in areas where static shock incidents are likely to occur, such as near electronic equipment, can greatly reduce the risk of static-related issues in these areas.

Design Static-Reducing Workstations

Your workstation layout can contribute to or reduce static buildup. To prevent static shock incidents, design each workstation in your workplace with static electricity reduction in mind. Minimize clutter and use cable management solutions to decrease static buildup and interference from cables. Also, securely connect all cables to reduce the risk of accidental disconnections and static-related issues.

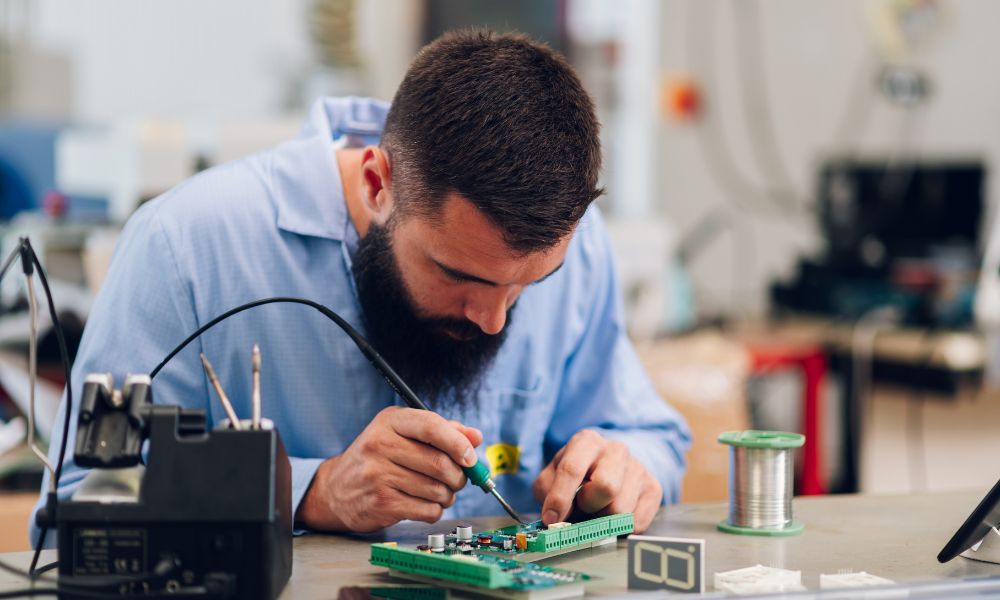

Handle Equipment Properly

Train employees on proper equipment handling practices to minimize static-related risks. Encourage them to ground themselves by touching a grounded object before handling sensitive electronic devices. Employees can also wear anti-static wrist straps while handling electronic equipment to ground themselves.

Store Equipment in Static-Safe Containers

Avoid using plastic bags or containers that can generate static charges when storing sensitive electronic components. Instead, store these components and devices in static-safe containers, like conductive bins and cabinets. These storage solutions have anti-static properties that prevent static from building up. Inform your employees of which storage areas are static-safe in order to prevent any static incidents.

Place Equipment in Static-Reducing Areas

The location of equipment influences its static buildup. Since moving air causes friction and more static charge, keep equipment away from areas with additional airflow, such as next to HVAC systems or near fans. When designing workstations, consider their placement in addition to their layout to prevent static incidents from occurring when employees use them.

Conduct Regular Inspections

After establishing static-reducing measures, continue to inspect and reevaluate them to ensure safety in your workplace. Regularly evaluate static control measures, incident reports, and employee feedback to identify areas for improvement. Stay updated on industry best practices and technological advancements in static control, and continue to make improvements to stay as safe as possible.

By incorporating these ways to prevent static shock in the workplace into your business, you can minimize static electricity buildup, reduce the risk of static shock incidents, and create a safer and more productive work environment. Prioritizing static electricity prevention protects employees and electronic equipment and improves workplace safety.